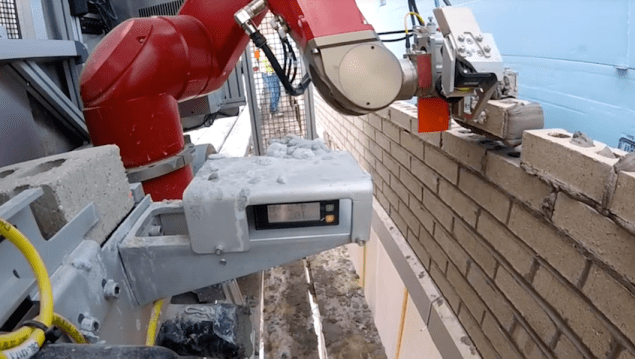

The construction industry utilizes machines in abundance to carry out their work in an efficient and flawless way. The latest additions to the industry to further improve the efficiency include drones, artificial intelligence (AI), and robotic tools, which, by far, are considered as the latest forms of technology.

What happens when cobots come to the scene?

Among the various robotic tools, cobots, also known as collaborative robots, are mostly preferred over exoskeletons and AM robotic arms, though they all perform the same tedious tasks, but reduces manual efforts and build structures autonomously. Usually robotic tools work at a closed space with barely any one in the vicinity. But, this is what makes cobots different. They are literally collaborative robots as they work in the same environment as humans to deliver tasks at a rapid pace and with quality.

Most of the staff time in construction companies is spent conducting on-site inspections. However, on-site monitoring gets easier, accurate, and automated with the use of mobile devices, sensors, scanners, and even autonomous drones and robots.

Over the years, there has been a decline in competitive workforce and as a result, there has been a comparatively lower productivity. To compensate for this, construction companies have turned to automation and robotics to lower down tasks that require intensive labour and to make the workforce more efficient. Also, it is the best way to recruit the tech savvy younger generation. Automation in the construction industry is compared to the manufacturing industry, which too has many herculean manual tasks to fulfill and has chosen automation as a solution.

Why cobots may still need time in the construction industry ?

At present, the major users of robotics are electronic, warehouse, and automotive industries; however, the innovations used in these industries can be used in construction as well. But the main problem is that adoption of cobots into all areas of the construction industry is not viable mainly because of the industry’s fragmented nature. Also, in the construction field, changes are made to the task process in real time. Therefore, adding robotic tools just to carry out certain tasks, while replacing a person will not be possible.

Also, bringing in robotics into the construction field requires huge capital investment. However, the industry has very low profit outcomes. By 2024, the cost of robotics and automation industries is expected to be $44.8 billion. There has also been reported growth in warehouse automation in the last several years; this has helped companies providing robotic services earn more.

Many organizations have been providing Robotics as a Service (RaaS), as a way to curb large expenditure in automation of construction industry. The RaaS model is affordable and goes well with industry practice to contract labor. This is done by organizations by leasing the robots for a year or so while paying a monthly fee in terms of service, repair, support, and operational optimization. It is also a way for the construction industry to slowly move away from outdated processes and the risks they possess. Though advantageous, construction companies may take a considerable time to learn about and adapt to these technologies. Therefore, efforts are being taken by the companies providing automation to develop robotic tools with the progress by workers to make sure that they can follow the present work practices.

Can automating the construction sector be truly beneficial?

Automating the construction industry can have some disadvantages too. Though sophisticated and takes up complicated tasks, it is not possible to hold the robots responsible when an error occurs and to correct them. The robots often require constant maintenance and service. If not, there is always a risk of errors occuring. Also, since the robots are merely tools and not a person, there are no contracts in place and no one is liable for the tasks they perform. In short, the rules regarding liability can never be applied to robots, no matter how big or small the risk is. Another problem is that the robots may not be familiar with all kinds of raw materials in the field. So, upon the introduction of a new raw material, the robots will not be able to complete the tasks as expected.

If the companies providing automation can find ways to solve the above-mentioned issues, the construction industry will definitely benefit from it. Check Out Here – about the latest applications of cobots in various sectors.

Leave a Reply